The installation process begins with a thorough assessment of your property’s cooling needs, taking into account factors such as square footage, insulation quality, window placement, and occupancy patterns. We calculate the precise cooling load requirements using Manual J calculations, an industry-standard methodology that determines the exact BTU capacity needed for your specific space. This detailed approach prevents the common pitfalls of oversizing or undersizing equipment, which can lead to inefficient operation, increased energy costs, and premature system failure.

Understanding Modern Air Conditioning Technology

Today’s air conditioning systems incorporate sophisticated technology that delivers superior comfort while minimizing environmental impact. Variable-speed compressors adjust cooling output based on real-time demand, maintaining consistent temperatures while reducing energy consumption by up to 40% compared to traditional single-stage units. Smart thermostats integrate seamlessly with these systems, enabling remote control through mobile devices and learning your preferences to automatically optimize comfort settings throughout the day.

The refrigerant transition from R-22 to R-410A represents a significant advancement in environmental responsibility and system efficiency. R-410A operates at higher pressures, allowing for better heat transfer and improved overall performance. Additionally, modern systems feature enhanced coil designs with micro-channel technology that maximizes surface area for heat exchange while reducing refrigerant charge requirements. These innovations contribute to SEER ratings exceeding 20, translating to substantial energy savings over the system’s lifespan.

The Installation Process: From Planning to Completion

Our installation process follows a meticulous sequence designed to ensure flawless execution and minimal disruption to your daily routine. Initial site preparation involves protecting flooring and furnishings while establishing clear pathways for equipment movement. The existing ductwork undergoes comprehensive inspection to identify any leaks, damage, or sizing issues that could compromise system performance. We seal all connections using mastic compounds and metal-backed tape, achieving duct leakage rates below 5% of total airflow.

Equipment placement requires careful consideration of multiple factors including drainage requirements, service accessibility, noise considerations, and local building codes. Outdoor condensing units need adequate clearance for proper airflow, typically maintaining minimum distances of two feet from walls and vegetation. Indoor air handlers or evaporator coils must be positioned to facilitate proper condensate drainage while maintaining accessibility for filter changes and routine maintenance. The refrigerant line set connecting these components requires precise routing to minimize length while avoiding potential damage sources.

Essential Components and Quality Standards

Every air conditioning installation involves critical components that must work in perfect harmony to deliver reliable cooling performance. The evaporator coil, housed within the indoor unit, absorbs heat from your indoor air as refrigerant evaporates within its tubing. We install matched coil sets designed specifically for your chosen condensing unit, ensuring optimal heat transfer efficiency and system longevity. The condensate drainage system includes primary and secondary drain lines with proper pitch and trap configurations to prevent water damage and microbial growth.

Electrical connections demand meticulous attention to safety and code compliance. We install dedicated circuits with appropriate amperage ratings, ensuring your new system receives clean, consistent power without overloading existing electrical infrastructure. Disconnect boxes provide convenient shutdown capability for service operations, while surge protectors safeguard sensitive electronic components from voltage spikes.

Maximizing System Performance and Longevity

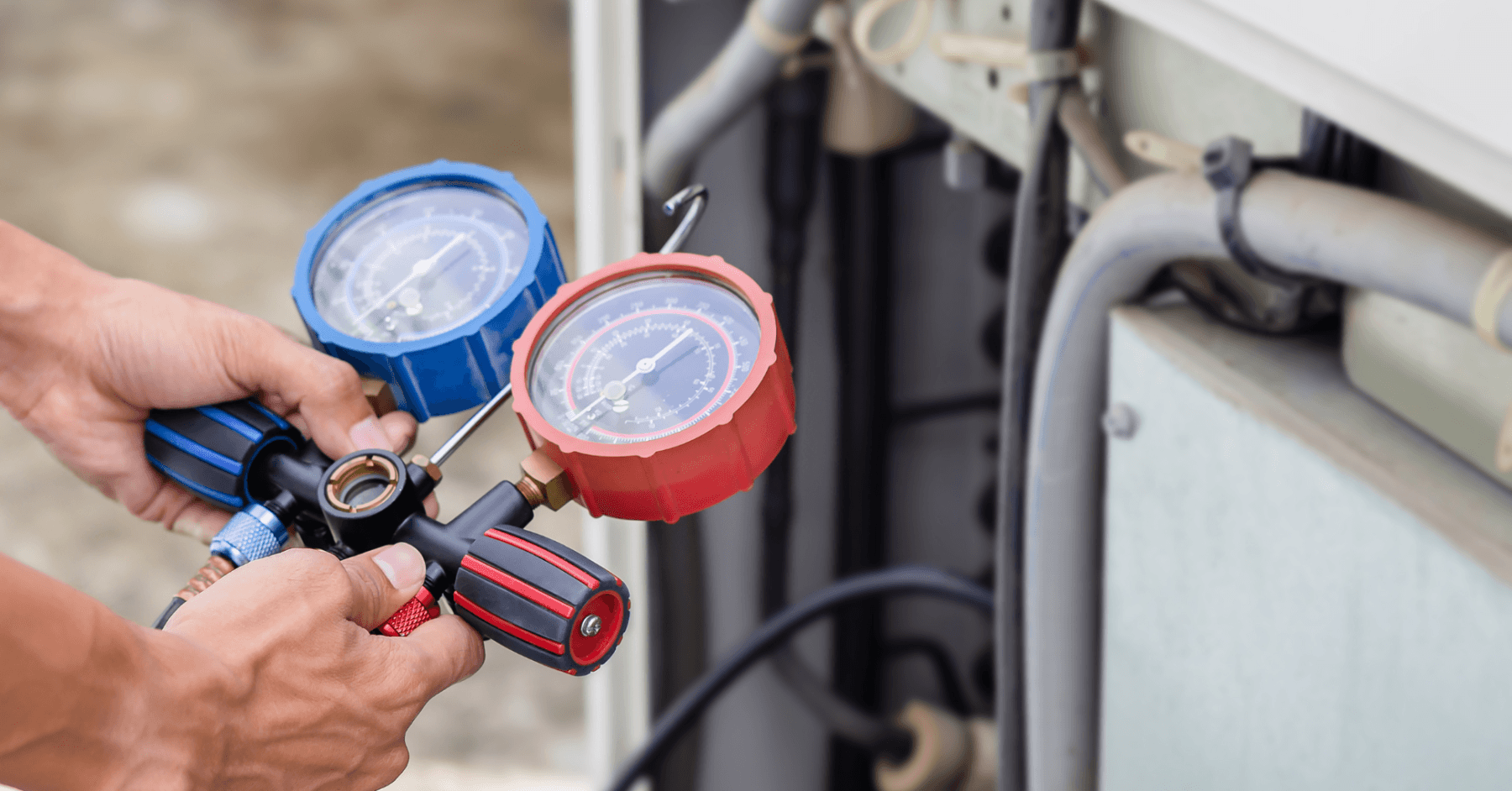

Proper installation techniques directly impact system performance, efficiency, and service life. Refrigerant charging requires precision instrumentation to achieve manufacturer-specified superheat and subcooling values. Our technicians use digital manifold gauges and temperature clamps to verify optimal refrigerant levels under various operating conditions. This attention to detail ensures maximum cooling capacity while preventing compressor damage from liquid flooding or excessive discharge temperatures.

Post-installation commissioning involves comprehensive testing of all system functions including airflow verification, temperature differential measurements, and control sequence validation. We document all readings and adjustments, providing you with detailed records for warranty purposes and future reference. If a problem occurs with your heating or cooling system, don’t panic, call Mannix! We have an outstanding reputation for customer service and have some of the most experienced techs in the industry. Just look us up on Angie’s List or read what others are saying about us on Google or Yelp. Our commitment extends beyond installation day through comprehensive maintenance programs designed to preserve peak performance throughout your system’s operational life.