These systems typically serve spaces ranging from 5,000 to 25,000 square feet, including retail stores, small offices, restaurants, medical clinics, and religious facilities. The complexity of light commercial HVAC extends beyond simple temperature control, encompassing ventilation requirements, humidity management, and indoor air quality considerations that directly impact employee productivity and customer satisfaction.

Light commercial systems differ significantly from residential units in their design, capacity, and operational demands. While residential systems might run intermittently based on homeowner preferences, commercial units often operate continuously during business hours, facing higher usage demands and requiring more robust construction. These systems must handle varying occupancy loads, equipment heat generation, and diverse comfort requirements across different zones within a single building. When a problem occurs with your heating or cooling system, don’t panic, call Mannix! They have an outstanding reputation for customer service and have some of the most experienced techs in the industry. Just look them up on Angie’s List or read what others are saying about them on Google or Yelp.

This is a job we did for an auto detail shop. This business had no AC whatsoever so we installed a new roof curb, cut a hole in the building roof, installed a new electric circuit, and installed some duct work.

Key Components and Technologies

Modern light commercial HVAC systems incorporate sophisticated technologies that maximize efficiency while maintaining precise climate control. Rooftop units (RTUs) remain the most common configuration, housing all components in a single package that sits atop the building, saving valuable interior space. These units typically range from 3 to 25 tons of cooling capacity and integrate heating elements, whether gas furnaces, heat pumps, or electric resistance heaters. Advanced control systems enable building managers to monitor and adjust settings remotely, schedule operation times, and receive maintenance alerts before minor issues become major problems.

Variable refrigerant flow (VRF) systems have gained popularity in light commercial applications across Gaithersburg, MD, Chantilly, VA, Treasure Island, FL and their surrounding areas, offering exceptional efficiency and zone control capabilities. These systems allow individual temperature control in multiple zones simultaneously, with some areas calling for cooling while others require heating. The technology uses refrigerant as the cooling and heating medium, eliminating the need for extensive ductwork and reducing energy losses. Split systems and ductless mini-splits provide flexibility for businesses with unique architectural constraints or those retrofitting older buildings where traditional ductwork installation would prove challenging or cost-prohibitive.

Energy Efficiency and Operating Costs

Energy efficiency stands at the forefront of light commercial HVAC considerations, with businesses facing increasing pressure to reduce operational expenses and environmental impact. Current industry standards require minimum SEER ratings of 14 for cooling and AFUE ratings of 80% for heating in commercial applications, though many businesses opt for higher-efficiency equipment to maximize long-term savings. According to the U.S. Department of Energy, HVAC systems account for approximately 40% of energy consumption in commercial buildings, making efficiency improvements particularly impactful on bottom-line results.

We recommend conducting comprehensive energy audits to identify optimization opportunities within existing systems. Simple improvements like programmable thermostats, regular filter changes, and proper insulation can reduce energy consumption by 10-30%. More substantial upgrades, including high-efficiency equipment replacement or building automation systems implementation, can achieve savings exceeding 50% compared to older, inefficient units. Federal tax incentives and utility rebates often offset initial investment costs, making efficiency upgrades increasingly attractive for budget-conscious businesses.

Maintenance Requirements and Best Practices

Preventive maintenance proves essential for maintaining peak performance and extending equipment lifespan in light commercial HVAC applications. We recommend establishing comprehensive maintenance programs that include:

- Quarterly filter replacements to maintain proper airflow and indoor air quality

- Semi-annual coil cleaning to prevent efficiency losses from dirt accumulation

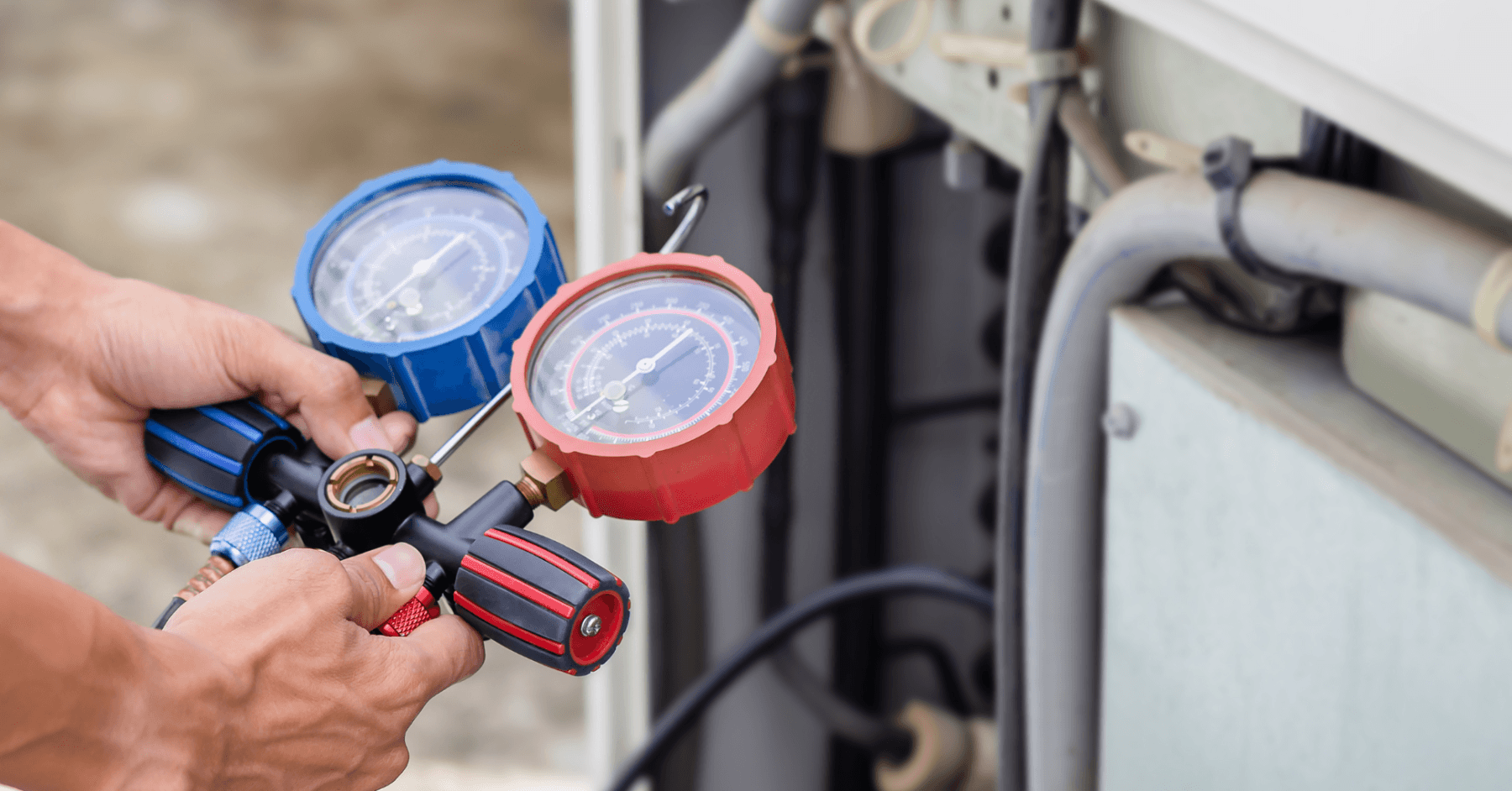

- Annual refrigerant level checks to ensure optimal cooling performance

- Belt and motor inspections to prevent unexpected breakdowns

- Thermostat calibration to maintain accurate temperature control

- Ductwork inspection to identify and seal air leaks

Regular maintenance typically reduces emergency repair calls by 75% and extends equipment life by 5-10 years beyond manufacturer expectations. Documentation of all maintenance activities helps maintain warranty coverage and provides valuable data for predicting future replacement needs.

Future Trends and Innovations

The light commercial HVAC industry continues evolving rapidly, driven by technological advancement and changing regulatory requirements. Smart building integration allows HVAC systems to communicate with other building systems, optimizing performance based on occupancy patterns, weather forecasts, and utility rate structures. Internet of Things (IoT) sensors provide real-time performance data, enabling predictive maintenance strategies that address potential issues before they impact comfort or operations. These connected systems help facilities managers throughout Gaithersburg, MD, Chantilly, VA, Treasure Island, FL and their surrounding areas make data-driven decisions about equipment operation, maintenance scheduling, and capital planning, ultimately reducing total cost of ownership while improving occupant satisfaction and environmental sustainability.