Our experienced technicians understand that each air conditioning system presents unique challenges based on its age, maintenance history, and operating conditions. We approach every repair with comprehensive diagnostic procedures, utilizing advanced testing equipment to identify the root cause rather than simply addressing symptoms. This methodical approach ensures that when we complete a repair, your system operates at peak efficiency, reducing energy consumption and extending equipment life.

Professional Diagnostic Process and Technical Expertise

The diagnostic process begins with a thorough visual inspection of your entire cooling system, including both indoor and outdoor components. We examine electrical connections, checking for signs of overheating, corrosion, or loose terminals that could cause intermittent failures or complete breakdowns. Voltage and amperage readings tell us whether components are drawing proper electrical current, while pressure tests reveal refrigerant levels and potential leaks within the sealed system. Temperature differential measurements across evaporator and condenser coils indicate whether heat transfer occurs efficiently, helping identify dirty coils, blocked filters, or failing fans.

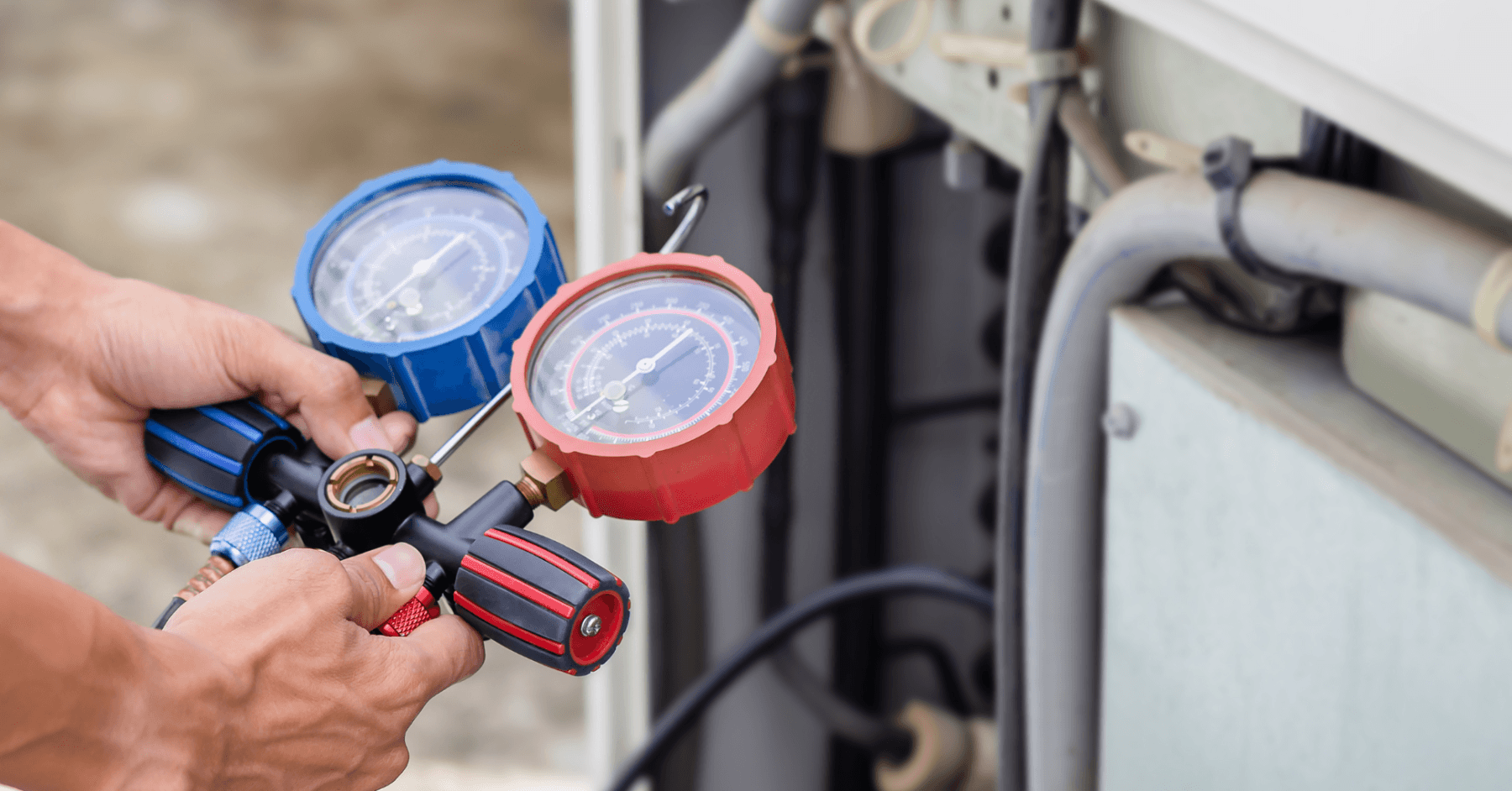

Advanced diagnostic tools allow us to detect problems invisible to the naked eye. Thermal imaging cameras reveal hot spots in electrical panels and motors before they fail completely. Digital manifold gauges provide precise refrigerant pressure readings, essential for proper system charging and leak detection. If a problem occurs with your heating or cooling system, don’t panic, call Mannix! We have an outstanding reputation for customer service and have some of the most experienced techs in the industry. Just look us up on Angie’s List or read what others are saying about us on Google or Yelp.

Component Repairs and Replacement Specifications

Air conditioning systems contain numerous components that work together to provide comfortable indoor temperatures. Compressors, the heart of any AC system, compress refrigerant gas into high-pressure liquid, generating the temperature differential necessary for heat transfer. When compressors fail, we evaluate whether repair or replacement makes economic sense based on the unit’s age, overall condition, and efficiency rating. Capacitors store electrical energy to start motors and keep them running smoothly. These components frequently fail due to heat exposure and electrical stress, causing motors to struggle or fail to start entirely.

Evaporator and condenser coils require special attention during repairs. These heat exchangers accumulate dirt, reducing airflow and heat transfer efficiency. We perform thorough coil cleaning using specialized chemicals and equipment, restoring proper heat exchange without damaging delicate aluminum fins. Fan motors, both indoor blower motors and outdoor condenser fan motors, operate continuously during cooling cycles. When bearings wear or windings fail, we replace motors with exact OEM specifications, ensuring proper airflow and system balance.

Emergency Response and Preventive Strategies

Throughout Gaithersburg, MD, Chantilly, VA, Treasure Island, FL and their surrounding areas, extreme summer temperatures make air conditioning essential for comfort and health. We maintain a 24-hour emergency answering service and offer emergency service through 11 pm, because we understand that AC failures don’t follow convenient schedules. Our service vehicles carry extensive parts inventories, enabling immediate repairs for most common issues without requiring return trips or ordering delays.

Preventive maintenance significantly reduces emergency repair frequency. During maintenance visits, we perform comprehensive system evaluations:

- Filter inspection and replacement: Clean filters maintain proper airflow and protect internal components from dust accumulation

- Refrigerant level verification: Proper charge ensures maximum cooling capacity and efficiency

- Electrical component testing: Identifying weak capacitors and connections before complete failure occurs

- Drain line cleaning: Preventing water damage from clogged condensate drains

- Thermostat calibration: Ensuring accurate temperature control and system cycling

Industry Standards and Technological Advancements

The HVAC industry continues evolving with new technologies and efficiency standards. Modern air conditioning systems achieve SEER ratings exceeding 20, compared to older units operating at 10 SEER or less. We stay current with these advancements through continuous training and manufacturer certifications. Variable-speed compressors and smart thermostats revolutionize comfort control while reducing energy consumption. These technologies require specialized knowledge for proper repair and optimization, expertise our technicians possess through extensive factory training programs.

Environmental regulations affect refrigerant types and handling procedures. R-410A replaced R-22 in new systems, requiring different pressures, oils, and service procedures. We maintain EPA certification for handling all refrigerant types, ensuring environmentally responsible service while maintaining system performance. Understanding these technical specifications enables accurate diagnosis and appropriate repair recommendations for any air conditioning system, regardless of age or manufacturer.