Our technicians examine existing ductwork for proper sizing and condition, as undersized or leaking ducts can reduce system efficiency by up to 30 percent according to industry studies.

The assessment phase also involves discussing your comfort preferences and understanding how different areas of your home are used throughout the day. Some homeowners prefer maintaining consistent temperatures throughout their property, while others want zone control capabilities to heat occupied spaces more efficiently. We analyze your current energy bills to establish baseline consumption patterns and project potential savings with newer, more efficient equipment. This detailed evaluation ensures that your new heating system will deliver optimal comfort while minimizing operational costs for years to come.

Selecting the Right Heating System

Choosing the appropriate heating system requires careful consideration of multiple factors beyond just the initial investment. Modern furnaces offer Annual Fuel Utilization Efficiency ratings ranging from 80 percent for standard models to 98 percent for high-efficiency units. Heat pumps have become increasingly popular throughout Gaithersburg, MD, Chantilly, VA, Treasure Island, FL and their surrounding areas, particularly dual-fuel systems that combine electric heat pump technology with gas furnace backup for extreme cold conditions. These systems automatically switch between electricity and gas based on outdoor temperatures and energy costs, maximizing both comfort and efficiency.

If a problem occurs with your heating or cooling system, don’t panic, call Mannix! We have an outstanding reputation for customer service and have some of the most experienced techs in the industry. Just look us up on Angie’s List or read what others are saying about us on Google or Yelp. Our expertise as a Carrier Factory Authorized Dealer means we understand the nuances of different heating technologies, from traditional single-stage furnaces to variable-speed models that adjust output incrementally based on heating demand. Variable-speed systems maintain more consistent temperatures, reduce temperature swings, and operate more quietly while using approximately 40 percent less electricity for air circulation.

Technical Installation Requirements

Proper heating installation demands adherence to strict technical specifications and local building codes. The installation process begins with preparing the installation site, which may involve modifying existing gas lines, electrical connections, or ventilation systems. Gas furnaces require proper venting to safely exhaust combustion gases, with options including traditional chimney venting, direct venting through exterior walls, or high-efficiency condensing units that use PVC piping. Each venting method has specific clearance requirements and installation protocols that must be followed precisely.

Electrical requirements vary significantly based on system type and capacity. While gas furnaces typically need only standard 115-volt connections for controls and blowers, electric furnaces and heat pumps often require 240-volt circuits with higher amperage ratings. Our certified technicians ensure all electrical work meets National Electrical Code standards and coordinate with licensed electricians when circuit upgrades are necessary. We also install proper condensate drainage systems for high-efficiency furnaces and heat pumps, which produce water as a byproduct of operation.

Installation Best Practices and Quality Assurance

During the actual installation, our team follows manufacturer specifications meticulously to preserve warranty coverage and ensure optimal performance. Key installation steps include:

- Proper unit leveling and mounting to prevent vibration and ensure correct condensate drainage

- Sealed duct connections using mastic sealant and metal tape to eliminate air leaks

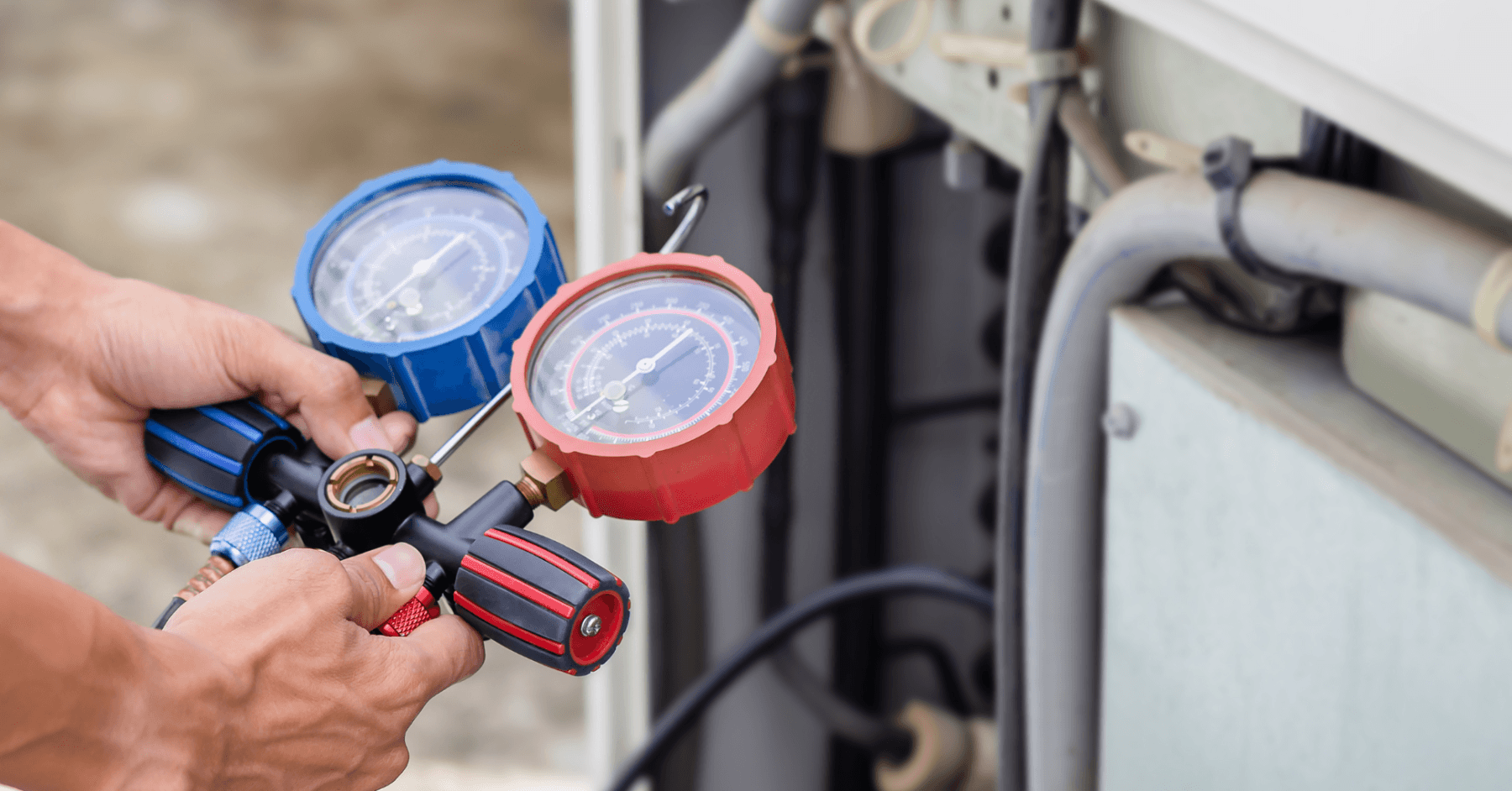

- Correct refrigerant charging for heat pump systems following manufacturer specifications

- Thermostat calibration and programming for optimal comfort and efficiency

- Safety control verification including limit switches and carbon monoxide detectors

After physical installation, we perform comprehensive system commissioning, which involves testing all operational modes, verifying proper airflow across heat exchangers, checking gas pressure and combustion efficiency, and ensuring all safety controls function correctly. This systematic approach identifies and resolves any issues before system handover, preventing callbacks and ensuring your complete satisfaction with the installation.