Maryland’s unique climate presents specific challenges that require deep understanding of regional weather patterns and their impact on HVAC systems. The state experiences hot, humid summers with average temperatures reaching 87°F in July, while winters can drop to 24°F in January. This 60-degree temperature swing demands robust systems capable of efficient heating and cooling transitions. Our technicians understand how Maryland’s humidity levels, which average 64% annually, affect system performance and indoor air quality, enabling us to recommend solutions that address both temperature control and moisture management.

Emergency Response and 24-Hour Service Coverage

When your heating or cooling system fails unexpectedly, immediate response becomes critical. Our 24-hour answering service at (301) 260-6000 ensures Maryland residents always have access to professional HVAC support. If a problem occurs with your heating or cooling system, don’t panic, call Mannix! We maintain emergency response teams ready to deploy throughout Montgomery County, typically arriving within two to four hours of your call during standard emergencies.

Our rapid response capability stems from strategically positioned service vehicles equipped with comprehensive parts inventories. Each technician carries diagnostic equipment capable of identifying issues in systems ranging from traditional split systems to high-velocity HVAC configurations. This preparedness means we can complete approximately 78% of repairs during the initial service visit, minimizing disruption to your daily routine and preventing extended periods without climate control.

Specialized Installation and Replacement Services

System installation represents a critical investment in your property’s comfort infrastructure. Our Maryland installation services begin with load calculations that consider square footage, insulation levels, window placement, and occupancy patterns. These calculations ensure proper system sizing, which industry studies show can reduce energy consumption by up to 30% compared to incorrectly sized units. We install Carrier HVAC systems as a Factory Authorized Dealer, maintaining strict adherence to manufacturer specifications and industry best practices.

The installation process involves multiple phases including existing system removal, ductwork evaluation and modification, electrical upgrades when necessary, refrigerant line installation, and comprehensive system commissioning. Our teams complete most residential installations within one to two days, though complex commercial projects may require additional time. Each installation includes thorough testing of all system components, verification of proper refrigerant charge, and airflow optimization to ensure maximum efficiency and longevity.

Preventive Maintenance Programs

Regular maintenance dramatically extends equipment lifespan while maintaining peak efficiency. Our maintenance programs include bi-annual inspections aligned with seasonal transitions, comprehensive cleaning of coils and condensate systems, filter replacements, electrical connection testing, and performance optimization adjustments. Industry data indicates that properly maintained systems operate 15-20% more efficiently than neglected units, translating to significant energy savings over the system’s operational life.

Advanced Diagnostic and Repair Capabilities

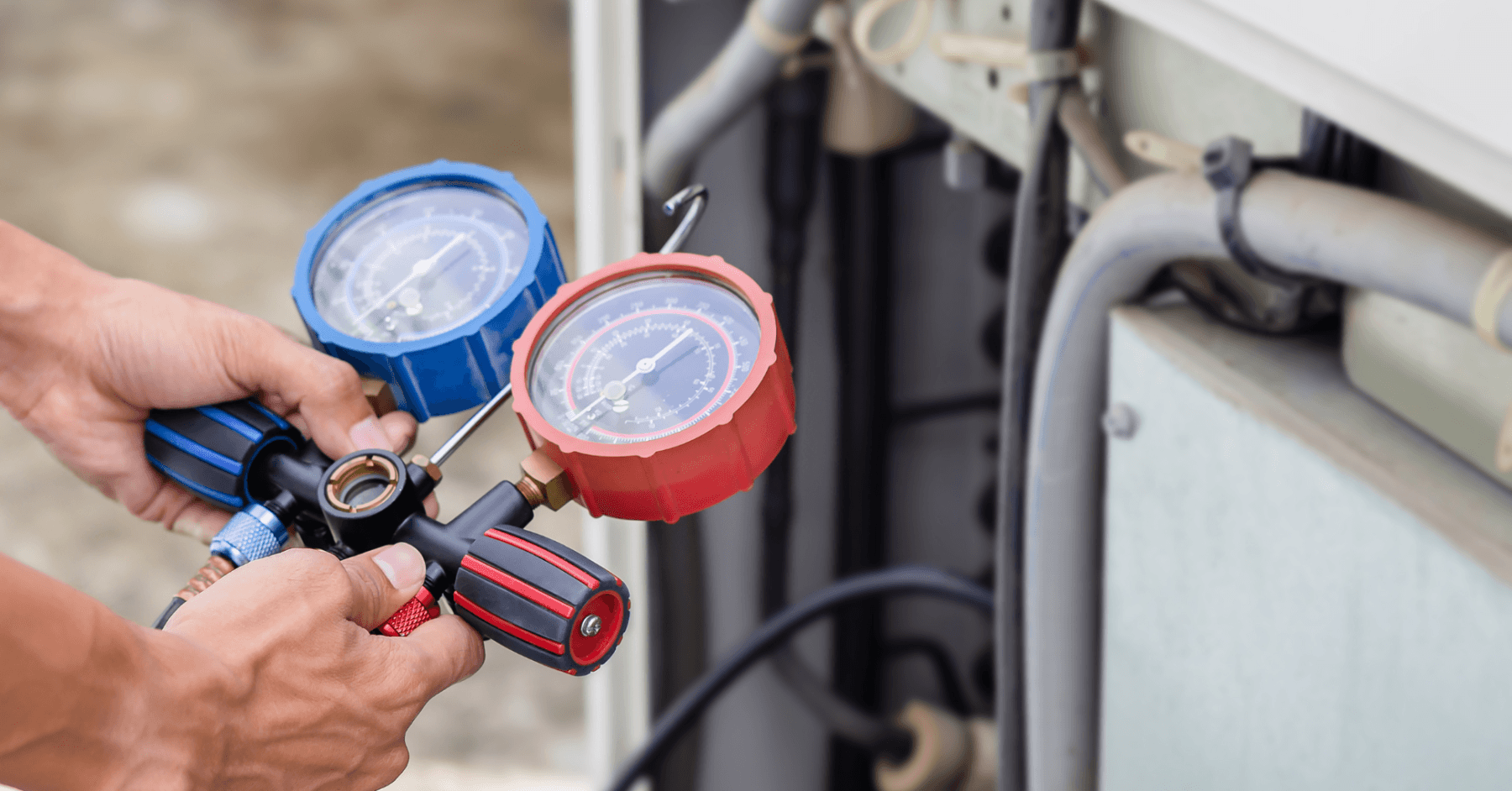

Our diagnostic approach combines traditional troubleshooting methods with modern digital analysis tools. We utilize infrared thermography to identify heat loss patterns, digital manifolds for precise refrigerant charge verification, and combustion analyzers for furnace efficiency testing. These tools enable identification of developing issues before they result in system failure, potentially saving thousands in emergency repair costs.

Common repair scenarios we address include:

- Refrigerant leaks: Detection using electronic leak detectors and UV dye systems, followed by EPA-compliant repair and recharge procedures

- Compressor failures: Comprehensive testing to determine whether repair or replacement provides optimal value

- Control system malfunctions: Troubleshooting of thermostats, control boards, and safety switches

- Airflow restrictions: Identification and correction of ductwork issues affecting system performance

- Heat exchanger problems: Safety inspections and replacement when necessary to prevent carbon monoxide hazards

Our technical expertise extends to emerging technologies including variable-speed systems, smart thermostats with learning capabilities, and zoned comfort solutions. We have an outstanding reputation for customer service and have some of the most experienced techs in the industry. Just look them up on Angie’s List or read what others are saying about them on Google or Yelp. This reputation reflects our commitment to continuous training and certification in evolving HVAC technologies, ensuring Maryland residents receive service that meets current industry standards while preparing for future innovations in climate control technology.